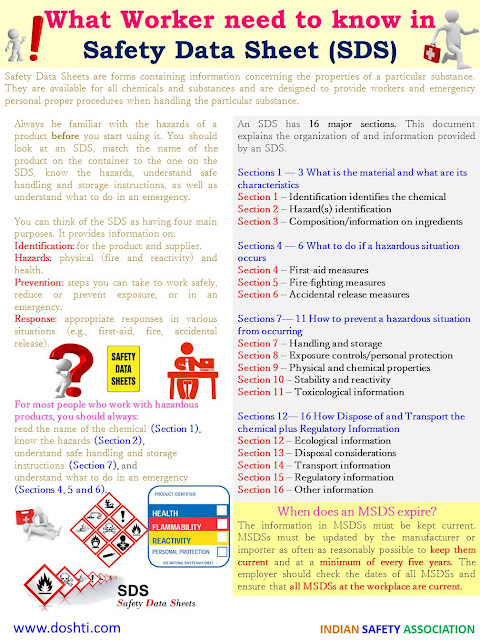

As mentioned above, osha requires this information to be divided into sixteen specific sections in accordance with ghs guidelines.

Osha safety data sheets include. Alongside the other upcoming osha changes we have talked about, the new regulations require a 16 section format for safety data sheets. Sdss are a widely used system for cataloguing information on chemicals, chemical compounds, and chemical mixtures.sds information may include instructions for the safe use. As of june 1 st, 2015, companies had to include sds whenever manufacturing, distributing, or importing hazardous chemicals. Safety data sheets were formerly called material safety data sheets (msds) by osha, but they have since adopted the sds name and standards.

Our training products on ghs safety data sheets review the composition of ghs safety data sheets, the information that's contained in each section and how sds's are different from material safety data sheets. Osha’s hazcom standard and other safety regulations around the world require employers to maintain a safety data sheet (sds) for every hazardous chemical in their inventory. Safety data sheets for hazard communication. Responding is kristen hogrefe, product manager, accuform signs, brooksville, fl.

For obvious reasons, section 2 of a ghs safety data sheet is often considered the most important section. Safety data sheets (mandatory) appendix d to the hazard communication standard, 29 cfr 1910.1200 [note: This is required by osha now, but is also part of the ghs system that should be. Classify chemical data and hazard criteria.

In 2012, osha modified its hazard communication standard (hcs or. A safety data sheet (sds), material safety data sheet (msds), or product safety data sheet (psds) are documents that list information relating to occupational safety and health for the use of various substances and products. Osha requires employers to maintain current safety data sheets (sds) on all chemicals used in the workplace, train employees on their use and make sds readily available in the work area. Topics covered in the program include:

The hazard communication standard (hcs) requires chemical manufacturers, distributors, or importers to provide safety data sheets (sdss) (formerly known as material safety data sheets or msdss) to communicate the hazards of hazardous chemical products. The order and placement of each section is not allowed to be altered. Before ghs, the requirements for msdss were confusing and not very detailed. The new requirements for safety data sheets include 16 specific sections that, according to osha, are “ensuring consistency in presentation of important protection information.” however, they are still similar to the old material safety data sheets in that they still contain information about the properties of a particular substance.

Since the list is rather long, we will be breaking it up into three posts. Osha requirements for safety data sheets include information about the physical, health and environmental hazards of each chemical as well as how to safely store, handle and transport them. The globally harmonized system of classification and labeling of chemicals (ghs) provides a single set of harmonized criteria for classifying chemicals according to their health and physical hazards and specifies hazard communication elements for labeling and safety data sheets. They are one of the most important documents a facility should have, as they address the properties of each chemical that workers use, transport, and handle onsite, including ones that are utilized only occasionally.

Do we need safety data sheets for drugs in our pharmacy? These informative documents are critical in keeping workers, patients and the environment safe. the hazard communication standard (hcs) specifies the required elements that must be on an sds among other important data. Identify a chemical's health, physical, and environmental hazards.

The whmis 2015 legislation is currently in force. Osha’s hazard communication standard and lab safety standard require chemical manufacturers, distributors, and importers to provide safety data sheets on the first delivery of a chemical, and upon request of the client. It contains hazard classifications, communication elements and the details of any other hazards which fall out of the scope of the eu hazardous substance classification system. However, there is a transition period with various stages.

The hazard communication standard (hcs) (29 cfr 1910.1200(g)), revised in 2012, requires that the chemical manufacturer, distributor, or importer provide safety data sheets (sdss) (formerly msdss or material safety data sheets) for each hazardous chemical to downstream users to communicate information on these hazards. This information comes from the chemical safety assessment that was carried In force means that suppliers may begin to use and follow the new requirements for labels and safety data sheets (sdss) for hazardous products sold, distributed, or imported into canada. Previously called msds (material safety data sheets) under the old osha hazcom standard, safety data sheets are a critical part of ghs and are designed to communicate complete information about a chemical or mixture and how to mitigate any issues with handling or storage.

Safety data sheets (sds) are an essential requirement to osha’s hazard communication standard. The importance of safety data sheets when working with hazardous chemicals. Today, osha’s hazcom standard (hcs) aligns with the ghs and “provides a common and coherent approach to classifying chemicals and communicating hazard information on labels and safety data sheets. Material safety data sheets and ghs sds's.

The occupational safety and health administration’s (osha) hazard communication standard details how healthcare organizations should inform employees about any hazardous chemicals to which they may be exposed at work. Safety data sheets however follow a particular. As of june 1, 2015, the hcs will require new sdss to be in a uniform format, and include the section numbers, the headings, and associated information under the headings below: Previously, safety data sheets functioned in the same way that the material safety data sheet (msds) did in the occupational safety and health administration’s (osha) hazard communication standard.

Hazard communication safety data sheets. There seems to be a lot of misunderstanding about the applicability of osha’s hazard communication standard (title 29, code of federal regulations, section 1910.1200) to medicines and drugs. Does osha require a specific format for safety data sheets under the revised hazard communication standard? Nsc’s training products on “hazwoper:

Topics covered in these products include: The written hazcom program must include information on container labeling, collection, availability of safety data sheets, and the employee training program. A key element of the standard relates to safety data sheets (sds). Safety data sheets have sixteen sections.

Safety data sheets” educate employees about the safety data sheets format and reviews how the information in an sds can help them work safely with potentially hazardous chemicals. The extended safety data sheets include an annex with exposure scenarios. Making safety data sheets (sds) readily accessible providing comprehensive staff training in 2012, osha began aligning the hazard communication standard with the globally harmonized system (ghs), a set of internationally created and approved criteria for classifying health, physical and environmental hazards. Chemical manufacturers are required to include an emergency phone number on the first section of the safety data sheet.

Provide safety data sheets (sdss) (formerly known as material safety data sheets or msdss) to communicate the hazards of hazardous chemical products.

Related topic:Provide safety data sheets (sdss) (formerly known as material safety data sheets or msdss) to communicate the hazards of hazardous chemical products. Chemical manufacturers are required to include an emergency phone number on the first section of the safety data sheet. Making safety data sheets (sds) readily accessible providing comprehensive staff training in 2012, osha began aligning the hazard communication standard with the globally harmonized system (ghs), a set of internationally created and approved criteria for classifying health, physical and environmental hazards.